How Is Digital Radiography Changing the NDT Industry?

August 15, 2025

Digital radiography (DR) is transforming the world of non-destructive testing (NDT), offering faster results, improved accuracy, and safer inspection methods. As technology advances, companies in the NDT industry are increasingly adopting digital radiography to enhance their inspection processes, reduce downtime, and ensure the integrity of critical materials.

What Is Digital Radiography in NDT?

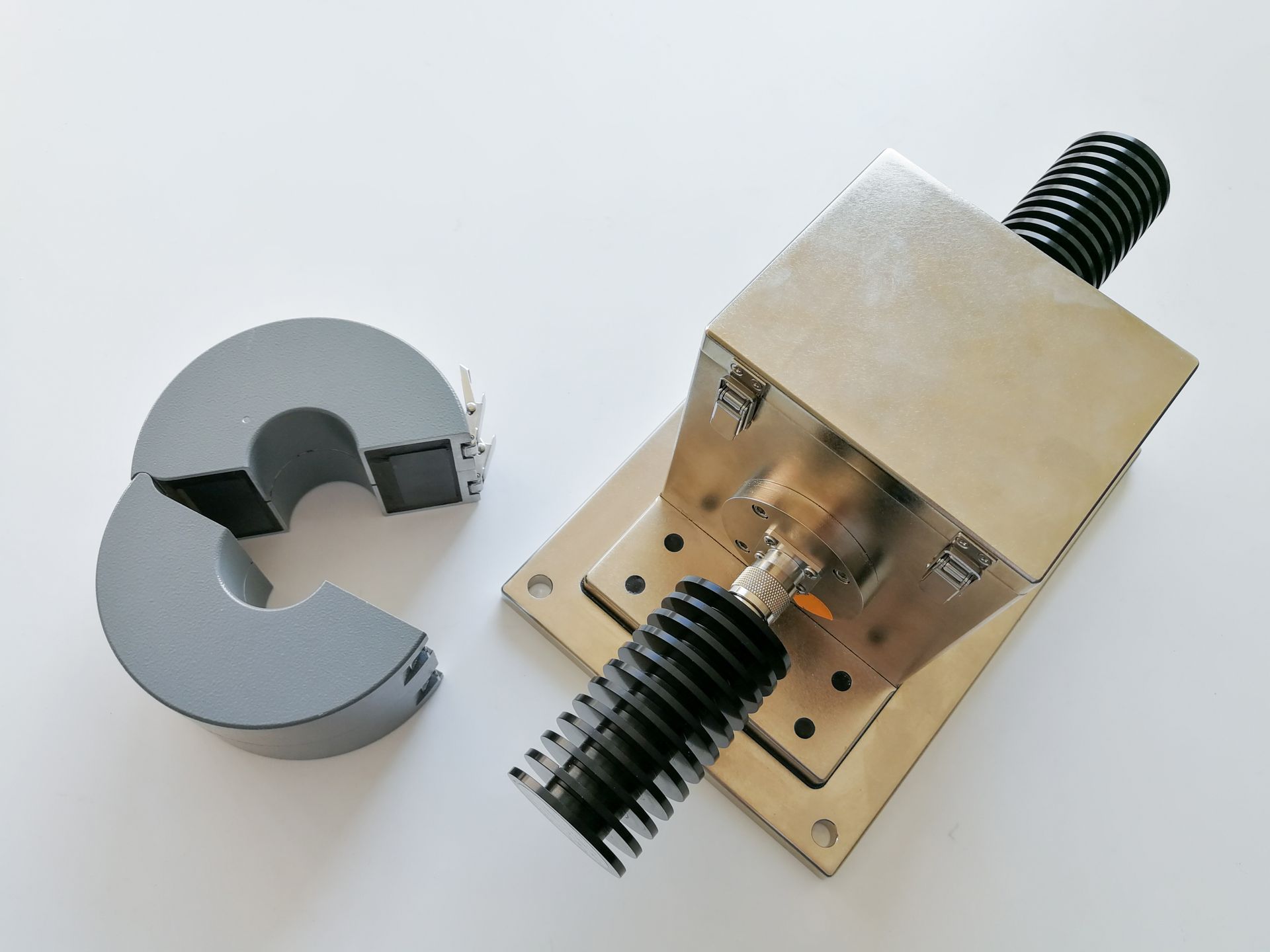

Digital radiography is a modern imaging technique that uses digital detectors instead of traditional film to capture images of a material’s internal structure. Unlike conventional X-rays, DR provides instant results, higher resolution images, and the ability to manipulate and analyze images digitally. This technology is widely used for inspecting metals, welds, composites, and other materials without causing damage.

Key Advantages of Digital Radiography in the NDT Industry

- Faster Inspection Times: DR reduces the time needed for inspections, allowing for near-instant image capture and review.

- Improved Accuracy: High-resolution digital images make it easier to detect defects such as cracks, porosity, or corrosion.

- Safer Processes: Reduced exposure to radiation compared to traditional methods improves safety for NDT technicians.

- Cost Efficiency: Eliminates the need for film development, storage, and disposal, lowering overall inspection costs.

- Enhanced Documentation: Digital images can be stored, shared, and analyzed efficiently, supporting better quality control.

How Digital Radiography Is Revolutionizing Inspections

Digital radiography is changing how companies approach inspections by enabling real-time monitoring and rapid decision-making. For industries like aerospace, automotive, energy, and construction, DR allows engineers and quality control teams to detect potential issues before they lead to costly failures. This proactive approach improves reliability, reduces downtime, and increases overall safety.

Real-World Applications of DR in the NDT Industry

- Weld Inspections: Ensures structural integrity in pipelines, bridges, and industrial machinery.

- Corrosion Monitoring: Detects internal corrosion in tanks, vessels, and piping systems.

- Composite Materials Testing: Ideal for aerospace and automotive components that require precise inspection without damage.

- Quality Assurance in Manufacturing: Ensures components meet safety and performance standards before shipping.

The Future of Digital Radiography in NDT

The adoption of digital radiography continues to grow, driven by advancements in AI, image processing, and automation. Integration with computer-aided inspection systems allows for predictive maintenance and smarter quality control. Companies investing in DR technology are positioning themselves to stay competitive and improve operational efficiency in the rapidly evolving NDT industry.

Conclusion

Digital radiography is not just a technological upgrade; it is a game-changer for the NDT industry. By providing faster, safer, and more accurate inspections, it allows companies to maintain higher quality standards, reduce costs, and improve safety.

If you’re ready to enhance your inspection capabilities and embrace the future of non-destructive testing, contact Steel City NDT today to learn more about our advanced digital radiography services.