The History of Magnetic Particle Testing

November 20, 2025

Magnetic particle testing is one of the most widely used non-destructive testing methods for evaluating steel components today. But its story goes far beyond modern laboratories. Over the last century, this technique has evolved through engineering breakthroughs, industrial challenges, and an increasing demand for accuracy in safety-critical environments.

At Steel City NDT, understanding where these methods began helps us appreciate how far inspection technology has come and why magnetic particle testing remains such an essential tool in the world of NDT.

1. Early Foundations in Magnetism and Materials

Before magnetic particle testing existed, scientists were already studying how magnetism interacted with metal flaws. In the late 1800s and early 1900s, researchers noticed that cracks in steel disrupted magnetic fields. When iron filings were sprinkled over magnetized metal, the filings gathered around the flaw, revealing its location.

This simple discovery became the foundation of what later became a formal inspection method.

2. The Birth of Magnetic Particle Testing in the 1920s

In the early 1920s, engineers working in the automotive and railroad industries needed a reliable way to detect cracks in steel parts before catastrophic failures occurred.

American engineer William Hoke is often credited with modernizing magnetic inspection. He used fine magnetic particles suspended in oil to reveal cracks in automotive components and refined the idea into a more controlled technique.

By the late 1920s, the process had evolved into a repeatable method used across multiple industries.

3. Advancements During World War II

As military equipment became more complex, the demand for safe, reliable steel components increased significantly. Aircraft, ships, vehicles, and weapons required rigorous inspection to ensure structural integrity.

During this era, magnetic particle testing advanced rapidly:

- Dry powders became more consistent

- Wet suspension methods improved visibility

- Portable magnetizing equipment became available

By the end of the war, magnetic particle testing was considered one of the most effective ways to locate surface-breaking defects in ferromagnetic materials.

4. Standardization in the Mid-20th Century

With industries adopting magnetic particle testing at a fast pace, the need for standardized procedures grew. By the 1950s and 1960s, organizations began to develop formal guidelines that ensured inspections were performed consistently.

Standards outlined:

- Proper magnetization techniques

- Particle types and color contrast

- Lighting conditions

- Calibration requirements

- Inspector training

These standards laid the foundation for the NDT certifications and inspection protocols still used today.

5. The Shift to Modern Equipment and Techniques

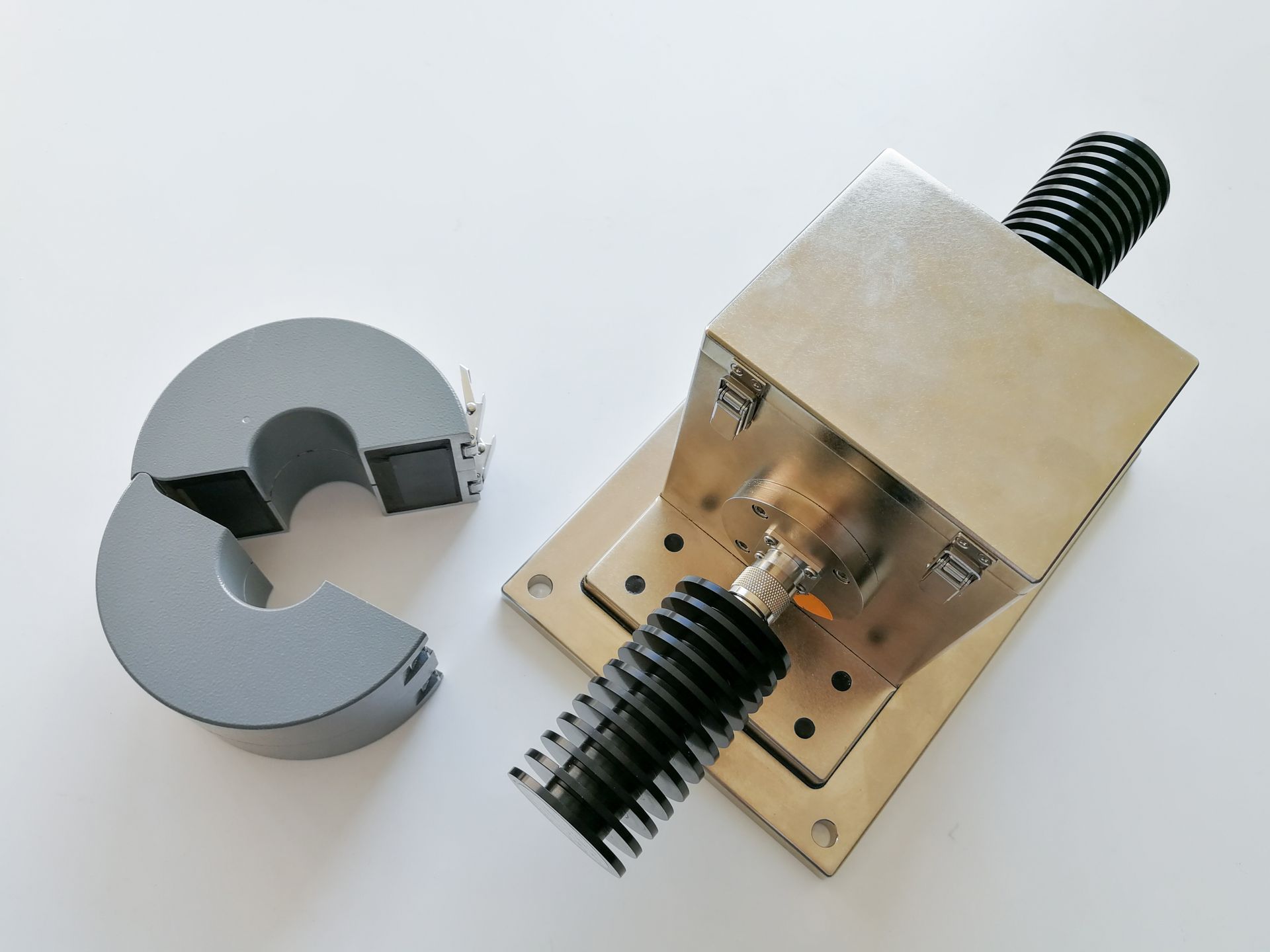

From the 1970s onward, technology transformed magnetic particle testing into a highly accurate and efficient method. Key improvements included:

- Stronger and safer electromagnetic yokes

- UV lighting for fluorescent particle inspections

- Cleaner, highly sensitive particle blends

- Better control of amperage and magnetic fields

- Digital documentation and inspection reporting

These upgrades improved defect visibility and made the method more precise than ever.

6. Where Magnetic Particle Testing Stands Today

Today, magnetic particle testing remains one of the most trusted NDT methods for detecting cracks, seams, laps, and other surface-breaking flaws in steel. It is widely used in:

- Structural steel fabrication

- Pipeline and pressure vessel inspections

- Automotive and transportation components

- Industrial machinery

- Welding inspection

Its affordability, sensitivity to small defects, and ease of use make it a go-to method for safety-critical inspections across industries.

At Steel City NDT, we continue to use advanced equipment and certified techniques to ensure accurate results that meet modern standards and industry expectations.

Conclusion: A Century of Progress with a Proven Future

From its simple beginnings with iron filings to the highly refined method used today, magnetic particle testing has undergone more than a century of innovation. Its evolution reflects the growing importance of safety, reliability, and precision in industrial environments.

As inspection technology continues to advance, Steel City NDT remains committed to delivering dependable magnetic particle testing services that honor the long history of this essential method while embracing the innovations that keep it moving forward.