Cause & Effect Corrosion in Amusement Rides

December 9, 2021

Corrosion on carnival/amusement rides is not only common, but it also can cause catastrophic failures as most recently seen in the Ohio State Fair accident which resulted in several injuries and one casualty. Not only is Steel City NDT LLC capable of testing for corrosion, but we are also able to tell you the extent of the corrosion.

Causes of Corrosion on Amusement Rides

- Corrosion is an electrochemical reaction that appears in a number of different forms

- A major cause of corrosion in amusement rides is due to acidic substances, most commonly rain, that creates rust over time

- Rust is the result of corroding steel, which takes place when the iron particles are exposed to oxygen and moisture (even humidity)

- When iron particles are exposed to oxygen, they become oxidized creating a cathodic area

- A corrosion pit is then formed where the affected iron particles were, and where they are now is called the corrosion product, or rust

Effects of Corrosion on Amusement Rides

- A decrease of tensile strength is a key effect of corrosion. The affected areas become thinned out due to corrosion, thus reducing the member’s maximum load threshold

- A member containing pitting corrosion is known to have a 2.5 times greater maximum load carrying capacity reduction

- A wider, larger member is said to have a lower stress threshold for crack initiation than that of a much smaller, thinner member when exposed to corrosion

- When pitting corrosion is involved, there is a greater negative impact on buckling strength

How Steel City NDT LLC Can Help

With the most recent accident at the Ohio State Fair, it was known that the specific ride which failed only underwent a visual examination. Not only this, but there are exponentially fewer inspectors than there are amusement rides in Ohio alone. Think about this from a Nationwide standpoint and you can see the problem immediately.

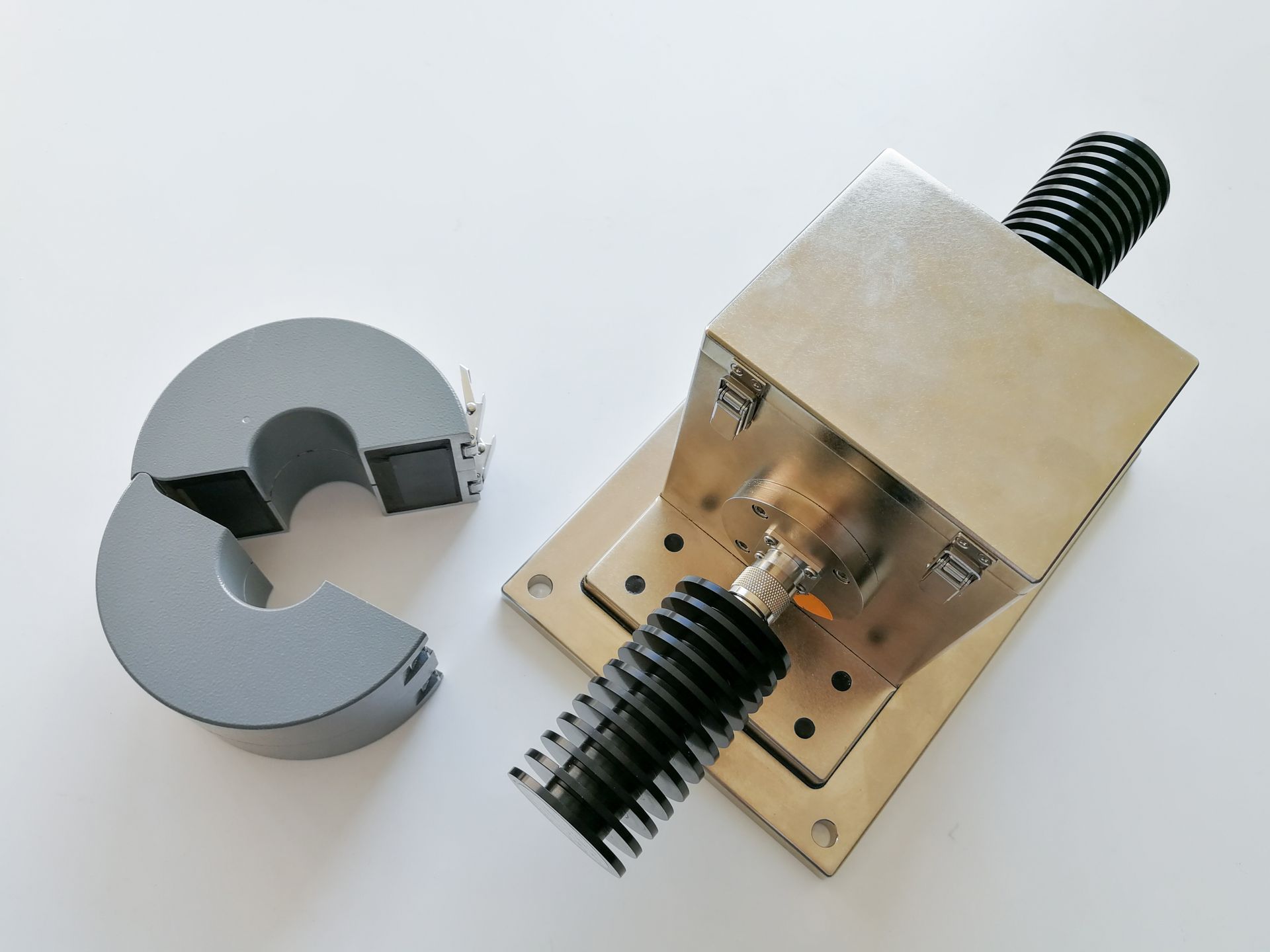

At Steel City NDT LLC, we offer a wide variety of inspection methods which can assist in not only locating corrosion, but determine the extent of corrosion within a majority of the members. Methods including, but not limited to, Ultrasonic Testing, Dye Penetrant Testing, and Magnetic Particle Testing will show anything happening beneath the surface (such as corrosion that cannot be seen with the naked eye). Had the ride at the Ohio State Fair been inspected with any of these methods, the failure could have been avoided altogether. Please contact us if a new or existing ride has not undergone an inspection within the past year.